In order to attach my “mystery build” to the trailer, I have two main problems to solve.

Most utility trailers are built to a maximum total width of 8′-6″. That’s the widest allowed dimension for road travel. And that’s measured to the outside of the wheel wells. Unless the trailer bed sits on top of the wheels (which mine does not), the actual trailer bed is smaller — typically 7′ or slightly less. To get the widest possible structure on the trailer, therefore, it needs to extend past the trailer frame on either side. But I didn’t want to cantilever floor joists, which would make it tricky to transfer the various loads between the framing and the trailer frame.

The second problem is to design a system that allows the structure to be one day separated from the trailer if necessary. For example, the structure could be installed on a permanent foundation and the trailer reused or sold. This rules out permanent and/or destructive solutions, such as welding anchor bolts to the trailer frame itself. If these anchor bolts terminated inside the walls, detaching the structure would require a lot of cutting.

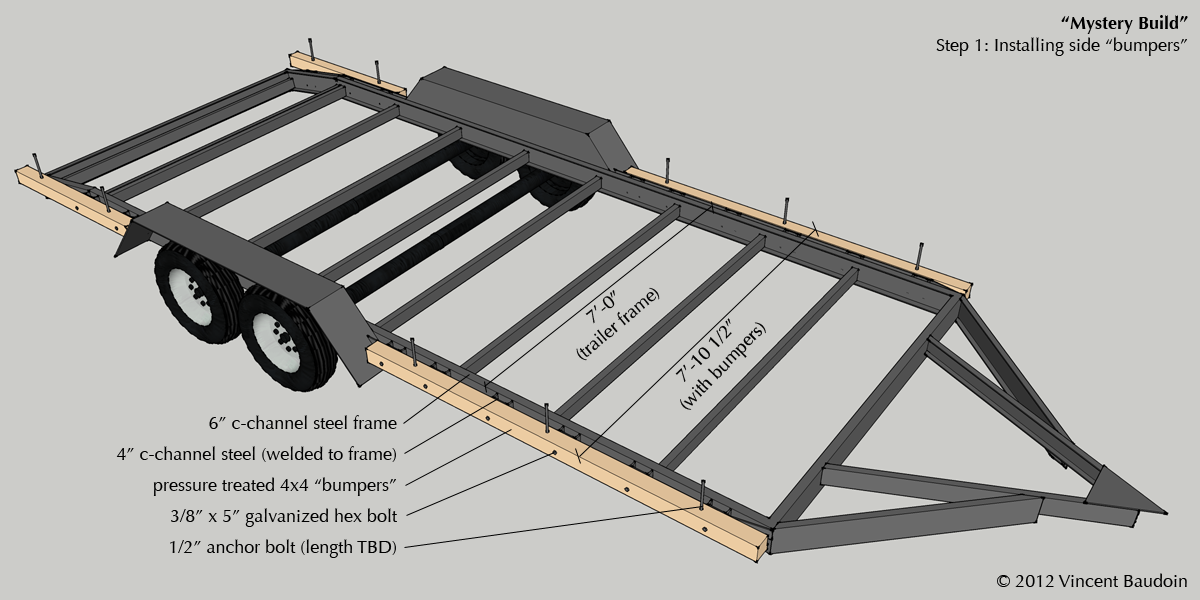

The solution that I am pursuing is to add 4×4 pressure-treated pine “bumpers” to either side of the trailer frame. Attached to the U-channel steel frame by 3/8″ galvanized hex head bolts, the bumpers extend the frame to 7′-10 1/2″ — just short of the 8′-0″ that I am aiming for, so I will run the floor framing 3/4″ long on either side. 1/2″ bolts will extend up through the floor framing and sole plate, attaching the walls securely to the bumpers.

The solution that I am pursuing is to add 4×4 pressure-treated pine “bumpers” to either side of the trailer frame. Attached to the U-channel steel frame by 3/8″ galvanized hex head bolts, the bumpers extend the frame to 7′-10 1/2″ — just short of the 8′-0″ that I am aiming for, so I will run the floor framing 3/4″ long on either side. 1/2″ bolts will extend up through the floor framing and sole plate, attaching the walls securely to the bumpers.

Drilling through hardened steel isn’t easy. I’m using cobalt/tungsten bits, predrilling with a 3/16″ bit and finishing with a 7/16″ bit. The key to drilling through steel is going at the right speed (slow) and using a cutting oil to prevent overheating. After about 5 holes, I’ve pretty much ruined the larger bit, so perhaps my technique isn’t that good yet.

Assuming I can finish the holes, I should be able to securely attach the bumpers. If the trailer needs to be removed, the 3/8″ bolts could be taken out and the whole structure jacked up by the bumpers. To make this work, something needs to be done to address the wheel well area, where there are no bumpers to support the floor and wall framing. I’ll expand on this more in a future post.

Comments and suggestions are welcome!

At least one mistake I noticed: I show the 4×4 being notched to accommodate the 1/4″ x 2″ steel band (shown but not labeled) on the outside of the 4″ U-channel steel. However, that would prevent the structure from being raised up off of the trailer, defeating the purpose.

Out of curiosity, could you elaborate on your concerns relative to cantilevering the floor joists? I am planning my own build and am of the perspective that cantilevering will work well for me, however I would love an opportunity to learn from you why that is not a good option for you.

Thanks in advance

Hi Patrick, good question. Basically, I wanted to be able to run a single long bolt up through the 4×4, the floor framing, the subfloor, and all the way through the bottom plate of the wall. (As shown in the image above, except I took the floor framing and wall in by 3/4″ so that the outside face of everything is flush.) I figured that this would give me the most direct connection from trailer to wall, to resist uplift or movement.

Besides, since my overall width was limited to 8′-6″, cantilevering would have gained me an couple inches of room at most — not worth it for me.

There’s no reason you couldn’t cantilever your floor joists. If you do so, however, you have two vertical connections to detail: the trailer-floor connection and the floor-wall connection. (As opposed to the single trailer-floor-wall connection in my case.) As long as you make those connections solid, you should be good to go.

I’d love to hear what you end up doing. And if you want to keep tabs on my project, future updates will be at my new site:

http://www.pilothousedesign.com/